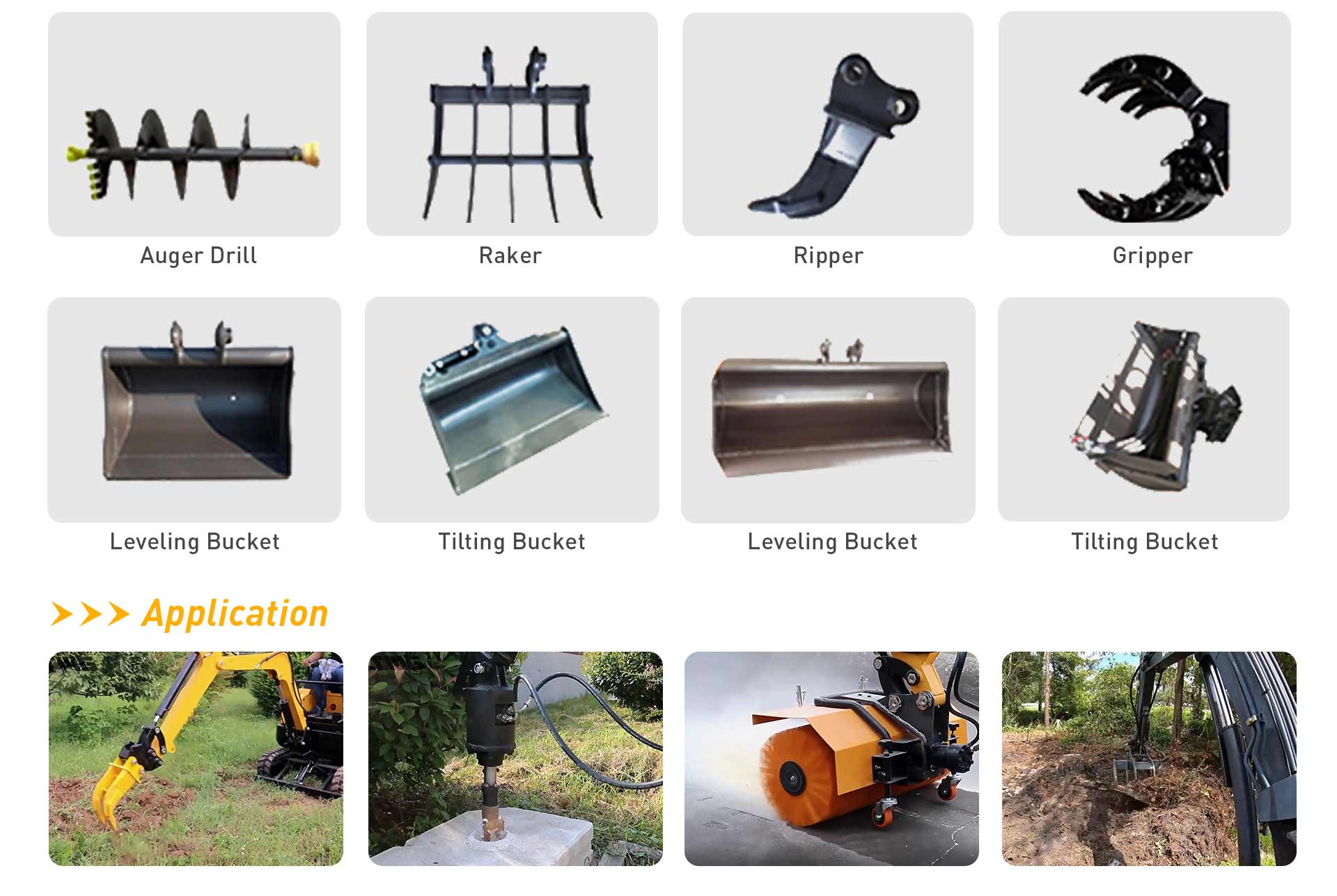

Come and see, the clever cooperation between the 3.5-ton mini excavator and its attachments is at work. LTMG small crawler hydraulic excavator is commonly used in small and medium-sized engineering environments. It can be used with a variety of excavator attachments.Different working environments and different attachments can achieve the goal of 1+1>2.

Model :

LTE35Operating Weight :

3810KGBucket Capacity :

0.12m³ODM/OEM :

Support

3.5 tons mini hydraulic crawler excavator LTMG brand

Product Features -- Hydraulic crawler excavator 3.5 tons LTMG

1. High power and efficient performance: The 3.5-ton hydraulic crawler excavator is equipped with a powerful hydraulic system and high-performance engine to provide excellent power and efficient working capabilities. This allows it to handle a variety of excavation jobs with ease, including tasks such as digging soil, extracting stone, and excavating infrastructure.

2. Stability and maneuverability: Hydraulic crawler excavators have a stable crawler system that can provide excellent maneuverability and stability in various terrains and working conditions. This allows it to operate accurately on uneven ground while also traversing narrow roads and construction sites with ease.

3. Versatility: This excavator is equipped with various excavator attachments, such as buckets, tongs, hammers, etc., which can be quickly replaced and adapted according to different work needs. This means that it can perform a variety of tasks, such as excavation, crushing, tamping, etc., improving construction efficiency and flexibility.

4. Ease of operation: Hydraulic crawler excavators have an intuitive operating interface and precise control system, allowing operators to easily master and operate the machine. It also has various intelligent functions, such as automatic balancing and intelligent identification, providing a more convenient operating experience.

5. Comfort and safety: The excavator is equipped with a spacious and comfortable cab with excellent sound insulation and shock absorption properties, providing the operator with a good working environment and comfort. At the same time, it is also equipped with a number of safety devices, such as anti-roll protection devices and emergency parking systems, to ensure a safe and reliable working process.

Product specifications -- Diesel hydraulic excavator 3.5 tons LTMG

| Model | LTE35 | |

| Enging | ||

| Engine Power | Kubota D170318.5KW/2200rpm | |

| Max. Turque | 97.4NLm/1500RPM | |

| Type | In-line, water cooled, Mechanical pump, nomally aspiraled | |

| Displacement | 1.647L | |

| No. of cylinder | 4 | |

| Main Performance | ||

| Swing Speed | rmin | 0-11 |

| Traveling Speed(high/low) | km/H | 4.4/2.4km/h |

| Grade ability | 58% | |

| Max. Bucket Digging Force | kN | 30.4 |

| Arm Dioging Foroe | kN | 18.2 |

| Ground Pressure | Kpa | 32 |

| Hydraulic system pressure | Mpa | 22.5 |

| Machine Weight | KG | 3810 |

| Boam Length | Mm | 2535 |

| Arm Length | Mm | 1400 |

| Fuel Tank capacily | L | 42 |

| Hydraulic Tank capacity | L | 48.5 |

| Engine oll capacity | L | 7 |

| Carrier roller(each side) | 1 | |

| Supporting roller(each side) | 4 | |

| Overall Dimensions | ||

| Overall Length | mm | 4915 |

| Overall Width | mm | 1720 |

| Overall Height | mm | 2525 |

| Mini Ground clearance | mm | 295 |

| Track width | mm | 300 |

| Axie base(Track length on ground) | mm | 1670 |

| ength of track | mm | 2154 |

| Track Gauge | Mm | 1420 |

| Swing radius at tail | Mm | 860 |

| Swing radius at front | Mm | 2538 |

| Height of blade | Mm | 350 |

| Operation parameters | ||

| Bucket Capacity | m² | 0.12 |

| Max. Digging Radius | mm | 5480 |

| Max. Digging Depth | mm | 3208 |

| Max. Digging Height | mm | 4800 |

| Max. Dumping Height | mm | 3406 |

| Max, vertioal digging depth | mm | 3208 |

With technological innovation, our product configuration and parameters will continue to change without notice;

if there is any doubt, the specific confirmation of our international trade sales shall prevail;

Excavator applications --LTMG track excavator with cab and air conditioning

LTMG's 3.5-ton hydraulic excavators come standard with hydraulic lines specifically designed for excavator fittings. It can be paired with different hydraulic or mechanical excavator accessories. It helps customers achieve different purposes in different working environments.

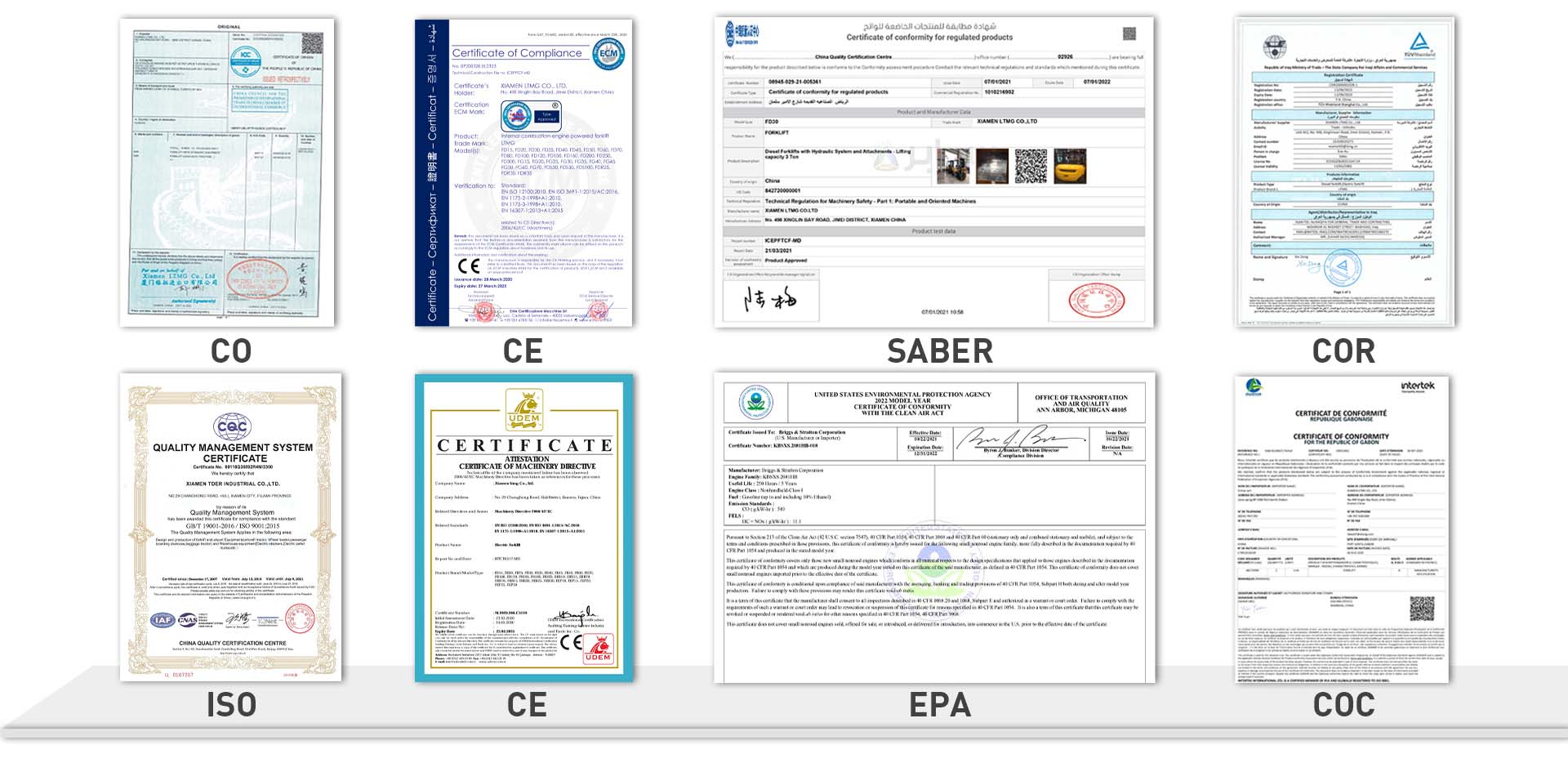

Product Certificate -- Diesel excavator small LTMG brand

LTMG has a number of certificates that meet the import requirements of our customers. Including CE certificate, ISO certificate, COC certificate.The certificates also help LTMG Machinery Group to work more closely with its customers.

FAQ

1: Why is it equipped with a thumb bucket?

Equipped with a thumb bucket can provide the following advantages:

Increased gripping capabilities: The thumb bucket allows the excavator to clamp and grab objects with hand-like functionality. It can easily grab and move a variety of objects including rocks, wood, pipes, etc.

Improved operational flexibility: The thumb bucket can rotate and tilt, allowing the excavator to better adapt to complex working environments and tight spaces. It enables the operator to control the excavator's movements more precisely, increasing work flexibility and accuracy.

2: Is there any additional cost for the installation of thumb bucket?

Yes, there is usually an additional cost to install a thumb bucket. The thumb bucket is an additional device that needs to be connected to the excavator's hydraulic system and properly adjusted and installed. Additionally, the cost of the thumb bucket itself needs to be considered. However, considering the features and benefits it offers, the cost of equipping a thumb bucket is often worth it, increasing your excavator’s versatility and productivity.

3. What are the key elements in the manufacturing process of the LTMG crawler excavator?

a. Material selection: High-quality materials are crucial to the durability of the excavator. The selection of high-quality steel and alloys can improve the strength and wear resistance of the excavator.

b. Design and manufacturing technology: Advanced design and production technology can ensure that the excavator has good structural strength and precise fit. This involves the experience and expertise of engineers.

c. Welding and assembly: Welding is an important process link in excavator manufacturing. High-quality welds provide rigid connections and good structural strength. Detail and quality control during assembly are also very important.

d. Surface treatment: Surface treatment of the excavator, such as spraying anti-rust agent and surface chrome plating, can improve its corrosion resistance and appearance quality.

4. How to evaluate the product quality of LTMG crawler excavator?

a. Experience and reputation: The experience and reputation of an excavator manufacturer are important indicators of the quality of its products. Manufacturers with extensive experience and a good reputation are usually able to provide high-quality products.

b. Quality control system: Manufacturers should have a sound quality control system to ensure that each production link undergoes strict monitoring and inspection. Quality certifications such as ISO 9001 are also a reference for evaluating manufacturers' quality levels.

c. Parts and accessories used: The quality of the parts and accessories used in the excavator directly affects the performance and life of the entire machine. Quality parts and accessories usually come from reputable suppliers.

d. Testing and certification: Excavator manufacturers should conduct strict product testing and certification to ensure that their performance meets relevant standards and requirements. CE certification and ISO 9001 certification are important guarantees of product quality.

Tags :