What are the major components or parts of a wheel loader?

Jan 23, 2024

Wheel loaders are heavy machinery designed for a vast array of applications across industries such as construction, mining, agriculture, and more. These versatile construction machines play a crucial role in handling material transport and earthmoving tasks efficiently. Behind the remarkable capabilities of a wheel loader lie its complex components, each serving a specific purpose in ensuring optimal performance. In this blog, let's delve into the major components that make up a wheel loader, shedding light on their functions and significance.

1. Chassis and Frame:

The chassis and frame form the backbone of a wheel loader, providing structural integrity and support. Constructed from high-strength steel, they endure heavy loads, vibrations, and stress encountered during operation. The frame connects the loader's key components, such as the engine, transmission, and axles, ensuring overall stability and durability.

2. Engine:

The engine is the heart of a wheel loader, providing the necessary power to drive the machine. Wheel loaders typically employ diesel engines, chosen for their robustness and torque output. These engines generate high levels of horsepower to efficiently move heavy loads and provide ample force for various hydraulic functions.

3. Transmission:

The transmission system in a wheel loader transfers power from the engine to the wheels, allowing for variable speed control. Most wheel loaders use powershift transmissions that enable smooth gear shifting even under heavy loads. These transmissions provide multiple forward and reverse gears, allowing operators to adapt to different working conditions seamlessly.

4. Axles and Tires:

Wheel loaders are equipped with heavy-duty axles that transfer power from the transmission to the wheels. These axles provide stability and maneuverability, regardless of the terrain. The robustness of axles is necessary to manage the weight and torque exerted by the machine during operations. Additionally, wheel loaders employ large and durable tires, specifically designed to withstand the intense loads and varied terrains encountered in their operational environments.

5. Bucket and Loader Arms:

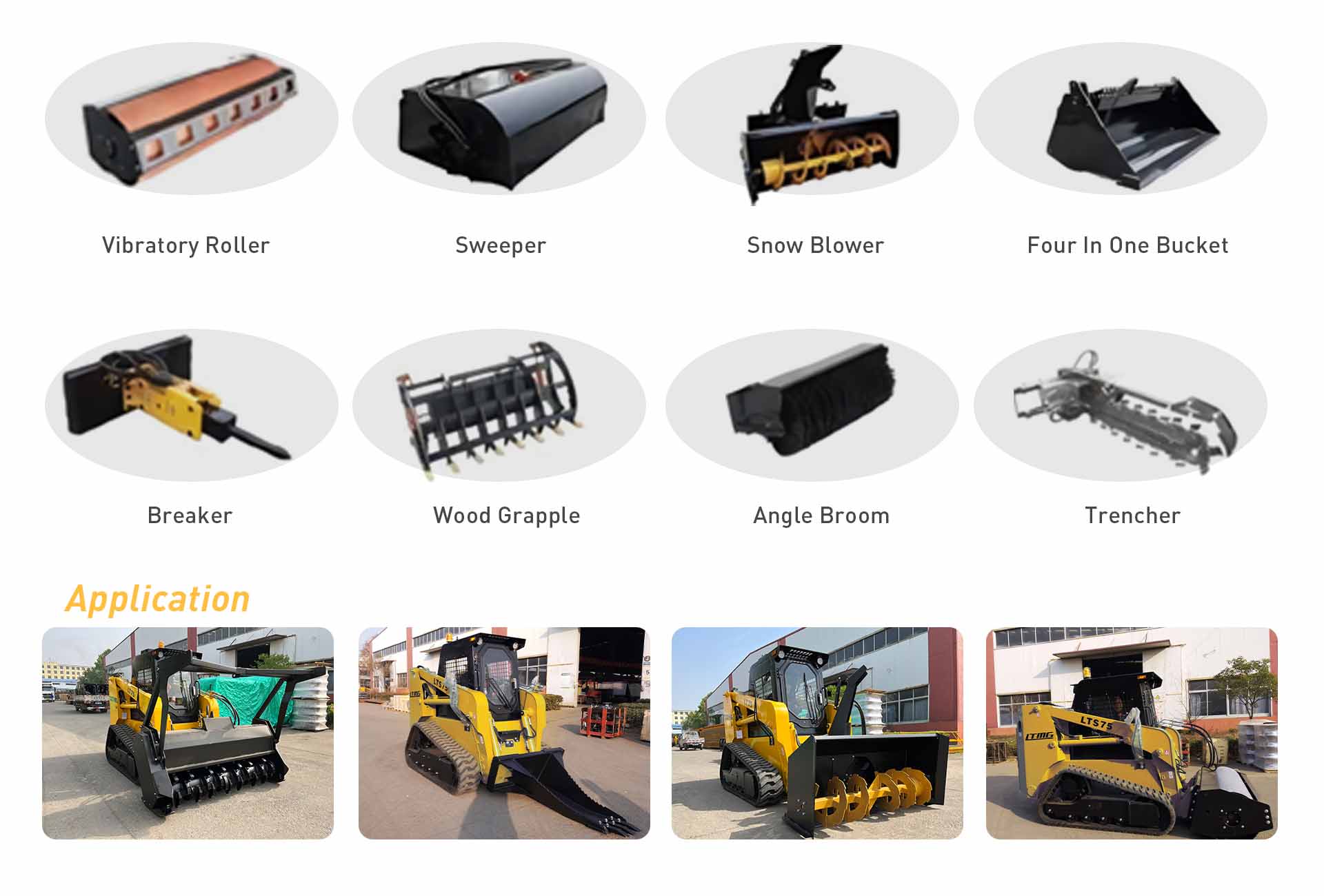

The bucket, located at the front of a wheel loader, is a key component responsible for material handling and loading. It comes in different sizes and configurations, such as general-purpose, rock, or high-dump buckets, tailored to suit specific applications. The loader arms, also known as lift arms or booms, support the bucket and provide the necessary lifting and lowering functions. The arms are hydraulically controlled, enabling efficient loading, dumping, and leveling operations.

6. Hydraulic System:

The hydraulic system of a wheel loader is vital for powering various functions, including the bucket and loader arm movements. It consists of hydraulic pumps, valves, cylinders, and hoses. The hydraulic system creates the required force to lift and lower the bucket, tilt it, and control other auxiliary attachments. Advanced wheel loaders often feature load-sensing hydraulic systems that optimize performance by delivering power when and where it's needed.

7. Operator's Cab and Controls:

The operator's cab is a crucial component in ensuring a comfortable and safe working environment for the wheel loader operator. It features ergonomically designed controls, adjustable seats, and excellent visibility to enhance operator efficiency and reduce fatigue. The controls allow the operator to manipulate the various functions of the machine, such as steering, shifting gears, and operating the hydraulic system.

Wheel loaders are complex machines composed of several interconnected components that work harmoniously to deliver outstanding performance in diverse applications. From the sturdy chassis to the powerful engine, precision hydraulic systems to versatile buckets, each component plays a distinct role in the efficient operation of wheel loaders.

LTMG, a leading provider of construction machinery, offers a range of high-quality wheel loaders that boast advantageous components. These powerful machines are built with key components designed to enhance performance and productivity. LTMG ensures that each component is carefully engineered and integrated to deliver optimal results on construction sites. Any interested or further question about the earthmoving machines, welcome to contact LTMG team. Our professional manager are willing to help you!